ODOUR CONTROL EQUIPMENT: BEWARE OF THESE COMMON MISTAKES

[vc_row][vc_column][vc_column_text]Odour control equipment plays a vital role in combatting odour issues. However, despite your best intentions, it’s easy to make simple mistakes. These can lead to inefficient equipment and spiralling costs. In this blog, we explore the most common mistakes operators make when selecting and operating equipment. We also offer valuable insights to help you avoid them.[/vc_column_text][vc_separator][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

ARE YOU MAKING THESE MISTAKES WITH YOUR ODOUR CONTROL EQUIPMENT?

[/vc_column_text][vc_column_text]

MISTAKE 1:

FAILING TO PLAN – Don’t Cut Corners

[/vc_column_text][vc_column_text]

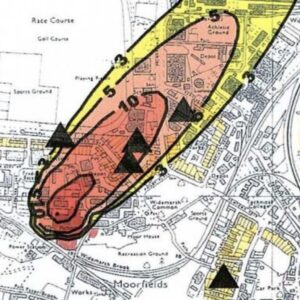

A dispersion model will indicate potential odour impact

Before investing in equipment, you can take simple steps to reduce odour emissions. Even small, inexpensive changes can make significant improvements. For example, seal doors, cover raw materials and dispose of waste promptly. You can then think about whether you need additional abatement equipment.

It is essential to cover all eventualities when designing your odour control equipment. If you cut corners, there’s a good chance that it won’t work. This will cost you more in the long run when you need to address the issues. The best way to achieve an effective design is by using odour dispersion modelling. Here’s why.

Understand the potential odour impact

Odour dispersion modelling helps you understand how odorous processes could impact the community. It will give you plenty of valuable information to consider in your decision-making. For example, how odours could spread from your site. It will also tell you how concentrated those odours might be. In addition, the data will highlight where the odours will likely have the most impact. For example, nearby residential areas, schools and businesses.

Make informed decisions and minimise costs

Using the data from odour dispersion modelling, you can make informed decisions. The insights will highlight how your site’s odour emissions could impact nearby areas. They will also identify which processes could cause the most odour issues. As a result, you can prioritise your investment and allocate resources effectively. This will yield the best results and help you avoid investing in ineffective measures.

Optimise the design of your odour control equipment

Odour dispersion modelling allows you to simulate different scenarios. For example, you can input different technologies, such as scrubbers or biofilters. You can also review whether stacks could help disperse the odour. The data will show which approach is most likely to be effective. This will help you optimise the design of your odour control measures and minimise odour

Ensure regulatory compliance

Dispersion modelling is useful in complying with your environmental responsibilities. You will have odour conditions outlined in your operating permits. The data can indicate whether your proposed equipment will comply with these conditions. As a result, you can avoid potential fines and legal consequences.[/vc_column_text][vc_separator][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

MISTAKE 2:

UNDERESTIMATING THE PROBLEM

[/vc_column_text][vc_column_text]

[/vc_column_text][vc_separator][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

MISTAKE 3:

MISORDERING ODOUR CONTROL PROCESSES

[/vc_column_text][vc_column_text]

[/vc_column_text][vc_separator][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

MISTAKE 4:

NEGLECTING MAINTENANCE

[/vc_column_text][vc_column_text]Maintaining odour control equipment is crucial. It allows you to ensure its efficiency and reduce ongoing costs.

Low sampling ports can make maintenance easier and more cost effective

Start thinking about maintenance when you plan new equipment. Consider factors like easy access to sampling, for example. For a tall stack, have you sited sampling ports low to the ground? There are lots of simple things like these, that you can put in place early on. Failing to do so creates unnecessary challenges for your maintenance team. This could lead to ineffective maintenance and costly upgrades.

Once your odour control equipment is operational, implement daily inspections. Choose a knowledgeable person to be responsible for these inspections. They should be well-versed in spotting potential issues. By conducting daily checks, they can catch and address emerging problems. They should also check odour control strategies are well stocked with the right materials and updated at the correct times.[/vc_column_text][vc_column_text]Here’s a great example of a failed maintenance routine: MP’s intervention solves biogas odour mystery | MRW[/vc_column_text][vc_message]Regular maintenance:

- enhances the efficiency and lifespan of your equipment

- limits the risk of breakdown

- avoids the need for costly repairs

- minimises complaints and conflict with the community

[/vc_message][vc_separator][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

SUPPORT WITH YOUR ODOUR CONTROL EQUIPMENT

[/vc_column_text][vc_column_text]Do you need help with your initial odour dispersion modelling? Or, perhaps you need odour sampling to check the efficiency of existing equipment? Whatever you need, Silsoe Odours can help. Our experienced odour specialists are well-versed in supporting clients with odour challenges. You can reach us on 01525 860222, info@silsoeodours.co.uk, or by clicking the button below.[/vc_column_text][vc_btn title=”Talk to us about your Odour Control needs today! ” color=”primary” size=”lg” align=”center” link=”url:https%3A%2F%2Fsilsoeodours.com%2Fcontact-us%2F|||” button_block=”true”][vc_separator][/vc_column][/vc_row]